Improved products

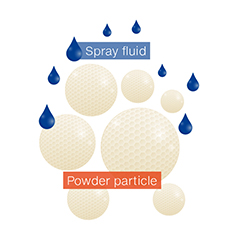

In agglomeration, fine powder particles are swirled through the system and combined into larger particles with the aid of water or special spray fluids. This technique is becoming more important, since it brings benefits for industrial processing and for consumers. Agglomerated powders pour better and are dust-free, and easer to make into tablets. Furthermore, additives like vitamins can be applied via the spray fluid. Fluidised bed technology offers a wide range of possibilities that let us meet the expectations of customers and consumers alike. These functions can be applied individually or in combination, depending on requirements. For accurate results, before we fill any large order we develop samples on our laboratory fluidised bed system. This is a big plus, because it lets us make adjustments before we go to scale

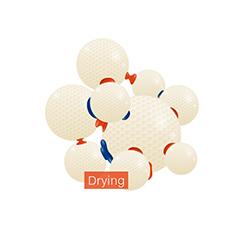

Compared to the starting product, powder agglomerates from fluidised bed drying are easier to dose and much easier to mix into liquids. The process results in pourable, easily dispersible grain structures that are also very low in dust. This last factor improves the hygienic situation in processing industries, and helps ensure problem-free, easy to clean, efficient operations. Through agglomeration, all individual components come together into a kind of homogeneous blackberry-like structure. This prevents subsequent segregation and provides for optimum process safety. Advantages at a glance:

Beverage powder in sachets or cans

Sample Application

Whether for convenience products like beverages and shakes, or for nutritional supplements and pharmaceutical excipients, instant powders and granulates need to dissolve quickly and without clumping. For this purpose, we develop individual processes to optimise the powder structure.

The goal is better dispersibility, solubility and flowability for your powder materials. The same goes for hydrocolloids, for example for thickening liquid meals to help people who have difficulty swallowing.

Tablet premixes

Sample Application

Your tablet production is more efficient with our granulate premixes. Why? Because the press quality of the tablets is higher and you can run your lines faster. What’s more, minimising the fine dust reduces cleaning effort and down time. These are advantages you can profit from.

Stevia as a sugar replacement

Sample Application

In the fluidised bed we can spray materials onto powders to create lasting combinations of things that might not otherwise go together readily, like different grain sizes and particle structures. The result is homogeneous blends that are impervious to stresses like long distance transportation.

Contact

SternMaid GmbH & Co. KG

Am Mühlenberg 4

19243 Wittenburg

Legal Information

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information