ONION LAYERING FOR SUBSTANCES

The granulates formed in spray granulation feature a round, compact structure. The result is a particularly pourable powder, with higher bulk density and tighter grain size distribution. Since these spray granulated blends are largely dust-free, they also bring advantages in further processing.

Individual settings

In spray granulation by fluidised bed you have many options. Residual moisture, grain size and bulk volume can all be individually adjusted within limits. We can also do spray granulation at very low temperatures, for very gentle granulation of heat-sensitive materials.

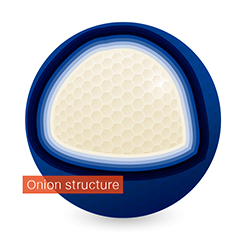

In spray granulation particles are successively coated by multiple layers. The fluid is sprayed onto the powder in the fluidised bed plant and gently dried onto the particles. This gradually builds wear-resistant grains with an onion-skin structure. Your advantages at a glance:

Capsule premixes

SAMPLE APPLICATION

Pharmaceutical and medical products need to be clean. Spray granulation reduces the amount of fine dust to a minimum. The low-dust granulates support the efficient production of capsules, among other things. Lines run better and capsules fill better. Cleaning processes are also better.

Vitamin-enriched teas

SAMPLE APPLICATION

Fine powders always seem to find a way to escape. To keep this from happening, we process substances of interest like vitamins into granulates. As larger particles, they are well protected and can deploy their effects where they’re supposed to, for example in a teabag in a good cup of tea.

Contact

SternMaid GmbH & Co. KG

Am Mühlenberg 4

19243 Wittenburg

Legal Information

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information