STATE OF THE ART

Whether soluble, pourable, dust-free, tabletable, masked or with ingredient protection, you define the product properties and we’ll make sure you get it. We improve and enhance your products with our state-of-the-art fluidised bed plant. Various processes like agglomerating, spray granulating, instantising and microencapsulation are available to us for the purpose. This lets us make individual powder and granulate products with which you as our customer are successful on the market.

The interplay of formulation and process parameters is the key to tailor-made properties and economic production. In the manufacturing of functional food, nutritional supplements, food additives and pharmaceutical excipients, fluidised bed technology has many advantages over other processes. This is particularly the case for thermo-sensitive products. The reason is that substances and starting blends can be enhanced in a fluidised bed plant even at low temperatures. This is a must for the gentle processing of sensitive enzymes and vitamins. Whatever your product requires in manufacturing, the process air temperature can be adjusted between 30 and 130°C.

We want to be flexible for our customers and offer everything possible in contract powder manufacturing. Accordingly, our fluidised bed system is multifunctional. It combines a wide range of technical possibilities, and can be run continuously as well as in batch operation. Our technical laboratory also features a lab-scale fluidised bed plant for custom product development. This way, in close dialogue with customers we can work up manufacturing processes and make test batches, which provide the basis for reproducible results later at industrial scale.

Agglomeration

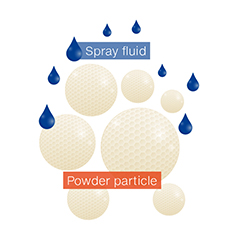

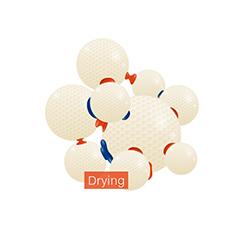

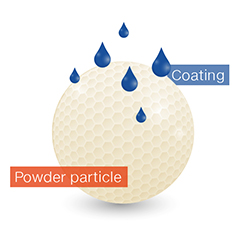

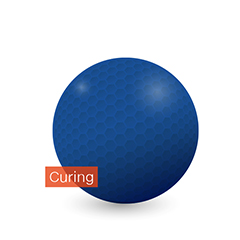

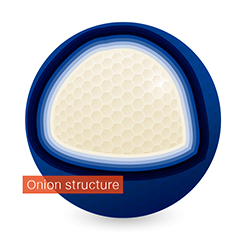

Microencapsulation

Spray granulation

Multifunctional system for granulation, agglomeration and microencapsulation

Gentle processing for thermo-sensitive products

Continuous or batch operation

Batch size approx. 250 – 500 kg

Top and bottom spray applications

Manifold equipment for preparing spray solutions

Numerous extra features like Wurster inserts, inline screening and milling

Laboratory fluidised bed plant

As shift manager on our fluidised bed plant, I keep things running smoothly and ensure product quality. I know every individual bolt, I know exactly how the system should sound and what it needs. I’m fascinated every day anew by fluidised bed technology and the things that we can use it to do with powders.

MATHIAS LIEHR,

SHIFT MANAGER

Contact

SternMaid GmbH & Co. KG

Am Mühlenberg 4

19243 Wittenburg

Legal Information

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Turnstile. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from hCaptcha to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Turnstile. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information